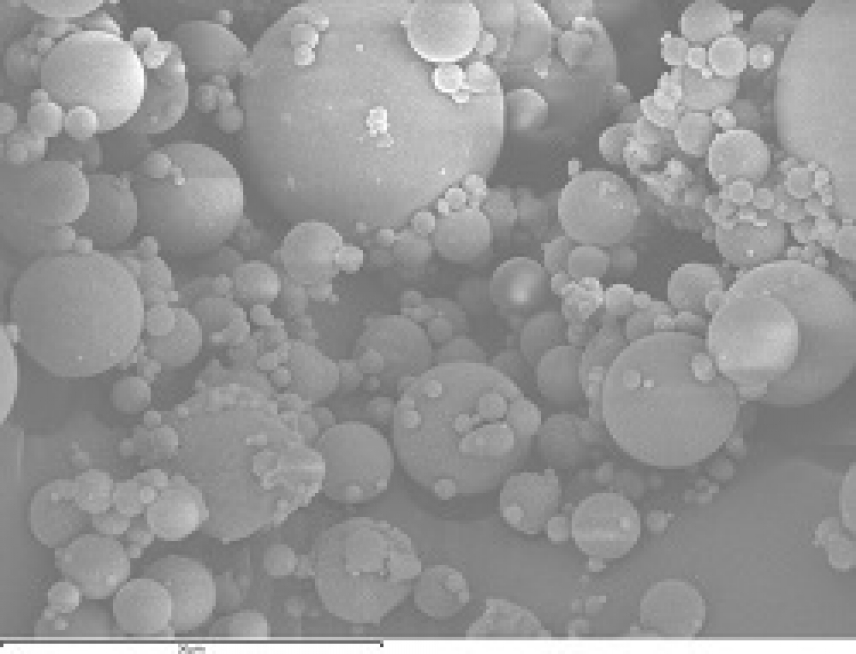

Specifically, the Materials and Applications (FQM391) research group headed by Professor José María Fernández and the Construction Engineering (TEP227) team headed by Professor José Ramón Jiménez were able to produce self-compacting concrete by substituting natural resources for waste derived from coal burning. In particular, these researchers successfully used non-conforming ash from thermoelectric plants instead of extremely fine particles from natural aggregates (siliceous filler) taken from rock quarries and cement mills.

This study, recently published in two issues of the journal Construction and Building Materials, consists of a physicochemical analysis of the ashes and then design and testing of mixtures with said ashes instead of extremely fine particles or fillers from quarries. All of this was done with an aim to produce a more environmentally friendly concrete. After several tests, the research group was able to manufacture concrete with enough suitable mechanical properties and durability to be used in construction. It took seven years of work to attain a self-compacting structural concrete with better features than concrete made with standard materials, as explained by the research directors.

In addition to optimizing natural resources and reclaiming waste, the work of the UCO researchers in partnership with the University of Navarra offers a solution to coal-fired thermoelectric plants. The fact is that fly ash accumulates in these plants and since there is no use for this ash, it ends up in controlled landfill sites. This study opens up a new possibilities to use this ash, thus changing its fate.

This new concrete is expected to be used in manufacturing prefabricated structural material such as beams, bearings and forged elements. The research team intends to industrialize this new concrete.

The fly ash used to carry out this research project comes from the Puente Nuevo thermoelectric plant, located between the towns of Espiel and Villaviciosa de Córdoba.

Esquinas, AR; Ledesma, EF; Otero, R; Jimenez, JR; Fernandez, JM. Mechanical behaviour of self-compacting concrete made with non-conforming fly ash from coal-fired power plants, CONSTRUCTION AND BUILDING MATERIALS. 182, 385-398. DOI: 10.1016/j.conbuildmat.20

Esquinas, A. R., Álvarez, J. I., Jiménez, J. R., & Fernández, J. M. (2018). Durability of self-compacting concrete made from non-conforming fly ash from coal-fired power plants. CONSTRUCTION AND BUILDING MATERIALS, 189, 993-1006. https://doi.org/10.1016/j.conbuildmat.2018.09.056